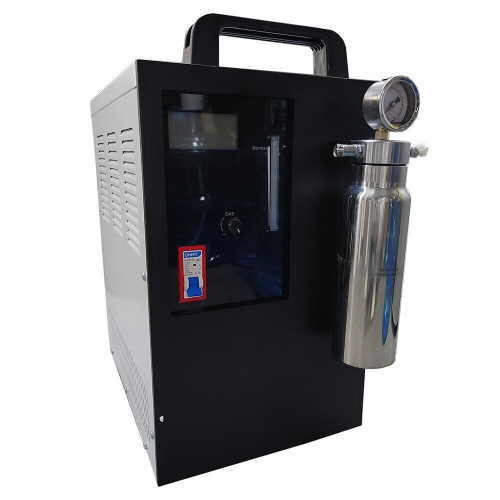

200A 1000W HHO Gas Water Hydrogen Flame Generator for Platinum Ring Welding, 230-250L with 2 Gas Torches free

Water welding machine 2 year warranty. Exceptional durability, the design life of electrolytic container is up to 10 years, and Electrical parts can be used within 5 years.

Used for:

The small 200A 1000W HHO gas flame generator is used for wide applications, such as jewelry welding, acrylic polishing, and ampoule bottle sealing etc. to replace use of LPG or other gas for fuel.

This HHO oxygen hydrogen gas flame generator is perfect for factory level user, looking to doing efficient work.

In jewelry industry, it is called “water welding machine” or “hydrogen & oxygen melting / welding machine”, while in organic glass industry, it is called “fire-polishing machine ”.

For welding, it featured low cost, welding fact, safety and low energy consumption.

Specifications:

Type: Industrial Machine

Main Applications: Acrylic polishing, melt welding, Jewelry Welding

Proper user: Factory level user (efficient work)

Power: 1000W

Gas flow: 230-250L

Torch & Nozzles: with 2 Gas Torch free

Flame power: Comparatively strong, efficient

Electrolyzing Tank: Double cases, 6 layers seamless tube

Total Volume: 4050ml

What is the Oxyhydrogen Generator Principle?

Oxy-hydrogen generator is also called brown gas generator,Acrylic Polishing machine , Water Welding Machine, or HHO gas generator, which is an integrated machine of utilizing the principle of electrolytic water to generate oxyhydrogen and ignite the mixed gas of oxyhydrogen to produce high temperature open fire. The surface of plexiglass gets melted meeting the fire then becomes smooth like polished. Hence, it is called the flame polishing machine. The precise and safe oxyhydrogen flame solves the difficulty of impossible polishing concave surface.

Model | SU-116 |

Type | Industrial Machine |

Main Applications | Acrylic polishing, melt welding, Jewelry Welding |

Proper user | Factory level user (efficient work) |

Power | 1000W |

Gas flow | 230-250L/hour |

Voltage | AC100V-240V, 50,60Hz |

Torch & Nozzles | with 2 Gas Torch free |

Flame power | Strong, for intensive operation |

Electrolyzing Tank | Double cases, 6 layers seamless tube |

Total Volume | 4050ml |

Pressure Auto-control | Pressure High Than 0.15mpa Switch off, Low than 0.09mpa Switch on. |

LCD Ampere Display | If indicating 150-160A Machine is making oxyhydrogen gas and working well. |

Gas Barometer | Low than 0.15mpa is right and safe, Oil inside for shockproof. |

Electrolyte (Alkali) | Prepare and add electrolyte at the first time of use. Change electrolyte when dirty or losing efficacy. |

Consumed Fuel | Water, from best to ordinary are: distilled water, purified water, cold boiled water, tap water and mineral water. |

Addictive | A little ethanol, other addictive or nothing, according to different use. |

Flame condition | Light blue, or blue / green with certain addictive. 1000-2800 degree centigrade, controlled with torch & nozzle. |

Pressure control | Gas generated while switch on, and stopped automatically when pressure exceed 0.1mpa. |

Indicating meters | DC ammeter indicates working current, shockproof barometer indicates gas pressure |

Safety fittings | Innovative backfire-proof fittings, intellectualized pressure switch, safety gas releasing valve and multilevel explode-proof design. |

Work environment | 0-50 degree centigrade well ventilated. Better 50cm above the ground. |

Addictive | A little ethanol, other addictive or nothing, according to different use. |

Torch & Nozzles | 2-3 Torches with Red copper nozzle A, B, C, D, & pinhole. Add 1 big nozzle 0.8mm. |

Water Feed | Manual |

Flame Modifier Feed | Manual |

Electrolyte (acrylic) | Must to add electrolyte at the first time of use. 500g electrolyte-powder mixed 2500ml water in an ovenproof plastic container. Change electrolyte when dirty or losing efficacy. 2 offlets in the bottom for changing. |

Consumed Fuel | Water. Only water, do not add electrolyte again. When the water level is lower than M line, please stop machine for adding water to near high line. From best to ordinary are: distilled water, purified water, cold boiled water, controlled water. Clean water is ok, but do not use mineral water. Water consumption: About 150ml/hour need to add water about every 4hours. |

Advantages:

Water Hydrogen Flame polishing welding machine possesses the following leading key technologies:

High Energy Conversion Ratio: The HHO gas generator polishing welding machine has high performance and high energy conversion ratio on the technology of special electrolysis power supply for large current. Can continuously run long time.

Super Long Lifespan: The technology of special anode material on anti-corrosion and anti-electro oxidation. The cathode stainless steel in resistance of electrochemical corrosion; the high efficiency electrolysis gas, heat emission, integration, long lifespan electrolysis tank processing technology. (The lifespan of anode is designed for 25000 hours, if we calculate by 8 hours a day and 300 days of working each year, the using lifespan will be more than 10 years.)

Operation is Safe Absolutely: The technologies of pressure sealing on oxyhydrogen mixed gas less than 0.3PA, anti-explosion and entire machine safety. The oxyhydrogen mixed gas is very flammable and explosive gas hence it easily causes internal explosion. It is required to ensure human safety in all the unexpected situations. With the leading technology backfire-proof oxyhydrogen flame gun, exquisite and precise in full brass quality.

Easy Operation: The mechatronic auto control system utilizes digital indicative application for which it selects digital ammeter, stainless steel pressure gage of oil-injection quakeproof, and stainless steel diaphragm pressure controller.

Appearance Patent: It is beautiful and durable. The appearance made of not only the stainless steel but also a protective structure of welded square tube. The precise shell made and formed by CNC equipment. The Application No. of Appearance

Energy Saving: Because the combustion of the oxyhydrogen gas generated by the electrolyte is the water vapour, and the oxyhydrogen gas has no toxicity and smell to human, and no harm to the environment too.

Remarks:

* The longer sized flame signifies sufficient fire it gives, and the higher polishing efficiency it provides. This is suitable for larger area polishing with high efficiency. If the flame is thin and shorter, it means there is not enough fire, the flame will scan smaller area and leave tack and result low efficiency which is generally attributed by the small machine with less power and gas. Normally, the flame can reach 5 cm long that satisfies common requirements. For different work pieces, the user shall choose related machines with correspondent power and flame. As for the very thin acrylic, please don’t use bigger fire.

*According to the thick or thin edge, choose the nozzle type and fire it with the lighter.

*The flame tilts 45 degree toward the edge. Keep a proper distance to scan it evenly.

*According to the practical experience, you should adjust the flame’s scanning distance, speed or change the nozzle. After a few rounds, you can skillfully operate the machine.

Water Hydrogen Flame polishing welding machine possesses the following leading key technologies:

High Energy Conversion Ratio: The HHO gas generator polishing welding machine has high performance and high energy conversion ratio on the technology of special electrolysis power supply for large current. Can continuously run long time.

Super Long Lifespan: The technology of special anode material on anti-corrosion and anti-electro oxidation. The cathode stainless steel in resistance of electrochemical corrosion; the high efficiency electrolysis gas, heat emission, integration, long lifespan electrolysis tank processing technology. (The lifespan of anode is designed for 25000 hours, if we calculate by 8 hours a day and 300 days of working each year, the using lifespan will be more than 10 years.)

Operation is Safe Absolutely: The technologies of pressure sealing on oxyhydrogen mixed gas less than 0.3PA, anti-explosion and entire machine safety. The oxyhydrogen mixed gas is very flammable and explosive gas hence it easily causes internal explosion. It is required to ensure human safety in all the unexpected situations. With the leading technology backfire-proof oxyhydrogen flame gun, exquisite and precise in full brass quality.

Easy Operation: The mechatronic auto control system utilizes digital indicative application for which it selects digital ammeter, stainless steel pressure gage of oil-injection quakeproof, and stainless steel diaphragm pressure controller.

Appearance Patent: It is beautiful and durable. The appearance made of not only the stainless steel but also a protective structure of welded square tube. The precise shell made and formed by CNC equipment. The Application No. of Appearance

Energy Saving: Because the combustion of the oxyhydrogen gas generated by the electrolyte is the water vapour, and the oxyhydrogen gas has no toxicity and smell to human, and no harm to the environment too.

Remarks:

* The longer sized flame signifies sufficient fire it gives, and the higher polishing efficiency it provides. This is suitable for larger area polishing with high efficiency. If the flame is thin and shorter, it means there is not enough fire, the flame will scan smaller area and leave tack and result low efficiency which is generally attributed by the small machine with less power and gas. Normally, the flame can reach 5 cm long that satisfies common requirements. For different work pieces, the user shall choose related machines with correspondent power and flame. As for the very thin acrylic, please don’t use bigger fire.

*According to the thick or thin edge, choose the nozzle type and fire it with the lighter.

*The flame tilts 45 degree toward the edge. Keep a proper distance to scan it evenly.

*According to the practical experience, you should adjust the flame’s scanning distance, speed or change the nozzle. After a few rounds, you can skillfully operate the machine.

APM-MS Series HHO Water Jewelry Welding Machine-Jewelry Tools and Supplies

When people buy jewelry, they mainly care about its fineness and craftwork. Welding technology is one of important process in the jewelry welding. And jewelry welding machine will be applied for the jewelry parts connection, jewelry inlaid, jewelry repair etc. HHO water jewelry welding machine is widely used in jewelry manufactures, stores or repairs. Today we mainly introduce you HHO oxy-hydrogen jewelry welding machine in the gold jewelry welding.

HHO oxyhydrogen jewelry welding machine’s features:

1. Hydrogen and oxygen is in the proportion of 2:1 after water electrolysis, which is also same combustion rate of hygrogen in oxygen gas. Compared with other gas fuels, it is not required to add extra mixed oxygen gas when burning.

2. Oxyhydrogen gas is blue flame when burning. And there is no carbon dioxide emissions producing. Compared with oxygen acetylene, oxyhygrogen flame is concentrated, its burning fast, low flame temperature and the combustion heat value.

3. Water and some electric as fuels, it is low cost, eco-friendly energy saving devices and safety, convenient for operation.

How to Operate the HHO Jewelry Welder Machine?

As usual, the left hands the hho, the right hand holds the forceps, because the right hand is more flexible, it can better pick up the smaller material, and adjust position of the components to be welded. The flame temperature of different materials is different, and it is necessary to adjust the flame continuously to ensure the welding part not to be deformed or melted.

If you are looking for jewelry tools and supplier, HHO welding machines will be your first consideration.

When people buy jewelry, they mainly care about its fineness and craftwork. Welding technology is one of important process in the jewelry welding. And jewelry welding machine will be applied for the jewelry parts connection, jewelry inlaid, jewelry repair etc. HHO water jewelry welding machine is widely used in jewelry manufactures, stores or repairs. Today we mainly introduce you HHO oxy-hydrogen jewelry welding machine in the gold jewelry welding.

HHO oxyhydrogen jewelry welding machine’s features:

1. Hydrogen and oxygen is in the proportion of 2:1 after water electrolysis, which is also same combustion rate of hygrogen in oxygen gas. Compared with other gas fuels, it is not required to add extra mixed oxygen gas when burning.

2. Oxyhydrogen gas is blue flame when burning. And there is no carbon dioxide emissions producing. Compared with oxygen acetylene, oxyhygrogen flame is concentrated, its burning fast, low flame temperature and the combustion heat value.

3. Water and some electric as fuels, it is low cost, eco-friendly energy saving devices and safety, convenient for operation.

How to Operate the HHO Jewelry Welder Machine?

As usual, the left hands the hho, the right hand holds the forceps, because the right hand is more flexible, it can better pick up the smaller material, and adjust position of the components to be welded. The flame temperature of different materials is different, and it is necessary to adjust the flame continuously to ensure the welding part not to be deformed or melted.

If you are looking for jewelry tools and supplier, HHO welding machines will be your first consideration.